Ejma Bellows Software Engineer

The Expansion Joint Manufacturers Association is an organization of established manufacturers of metal bellows type expansion joints. Roland Vst Rapidshare Files. EJMA was founded in 1955 to establish and maintain quality design and manufacturing standards. These Standards combine the knowledge and experience of the association’s Technical Committee and are available to assist users, designers, and others in the selection and application of expansion joints for safe and reliable piping and vessel installation. EJMA carries out extensive technical research and testing on many important aspects of expansion joint design and manufacturing. EJMA 10th Edition is the most current edition and supersedes all previous publications. Triad Bellows Design and Manufacturing uses bellows design software based on EJMA 10th edition guidelines. Cd: The factor read from the EJMA Figure C26 (or ASME VIII) for the listed curve number and x value.

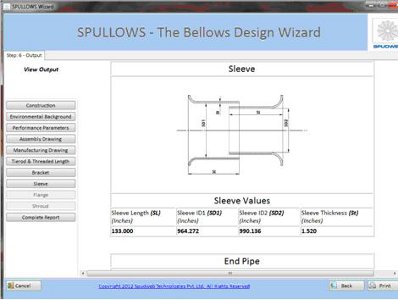

Stress Analysis of Piping. PIPING GUIDE. The analysis of piping under pressure, weight and thennal expansion is complex. This complexity can be understood. We design and engineer the Metal Bellows Expansion Joints fully. As a member of EJMA, U.S. Bellows Master. Our bellows software design programs are.

It is used in specific design calculations to relate U-shaped bellows convolution segment behavior to a simple strip beam. Cf: The factor read from the EJMA Figure C25 (or ASME VIII) for the listed curve number and x value. It is used in specific design calculations to relate U-shaped bellows convolution segment behavior to a simple strip beam. Cp: The factor read from the EJMA Figure C26 (or ASME VIII) for the listed curve number and x value. It is used in specific design calculations to relate U-shaped bellows convolution segment behavior to a simple strip beam. S1: Bellows tangent circumferential membrane stress due to internal pressure. In case of external pressure the reinforcing effect of a possible external collar is excluded.

S1: Collar circumferential membrane stress due to internal pressure. In case of external pressure the reinforcing effect of a possible external collar is excluded. S2: Bellows circumferential membrane stress due to pressure. S3: Bellows meridional membrane stress due to pressure. Software Serial Esp8266 Pinout. S4: Bellows meridional bending stress due to pressure.

S5: Bellows meridional membrane stress due to deflection. S6: Bellows meridional bending stress due to deflection. Rated Max Axial: The maximum amount of movement (axial extension, axial compression, lateral deflection, angular rotation, or any combination thereof) which an Expansion Joint is capable of absorbing.